Heavy Duty Height Safety with a Small Foot Print & Larger Working Area

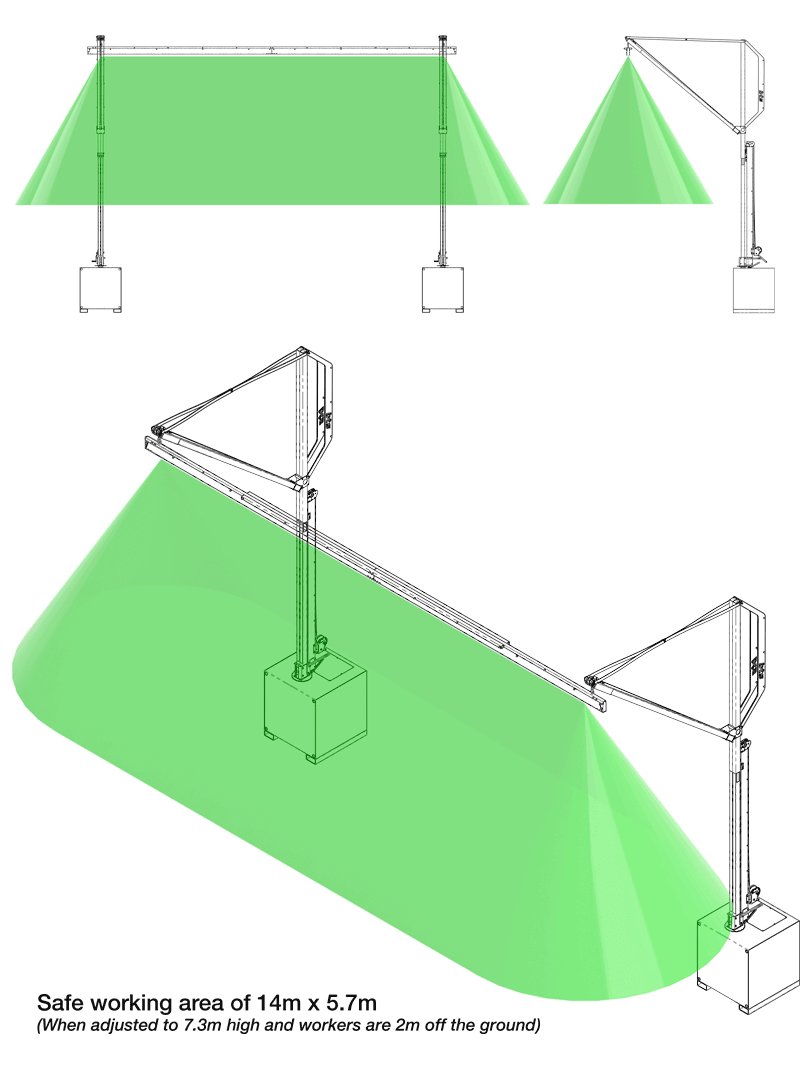

The BTS Restricted Space Cube (RSC) & Horizontal Rail combination provides 2 persons working at heights an overhead anchor point that is modular and can be moved easily around a site either via a forklift or hand pallet jack. The Cube & Horizontal Rail combination is an ideal solution for sites where an overhead structure or existing anchor point may not be suitable. Available with an adjustable height of up to 7.3m and a working area of 14m x 5.7m (When adjusted to 7.3m high and workers are 2m off the ground).

Diverse range of applications

The Cube & Horizontal Rail combination is a suitable fall protection device for a diverse range of applications including, maintenance on a large variety of vehicles, aircraft, earth moving plant equipment, rolling stock, highway and off highway trucks, shipping containers, portable buildings and any other plant equipment that require access and involve working at heights. This combination can also be adapted as part of a truck loading and unloading process in warehouse and distribution facilities.

The BTS Restricted Space Cube (RSC) & Horizontal Rail combination is designed with a minimal footprint allowing it to be positioned close to the equipment being accessed all while providing maximum fall protection for the worker.

BTS Restricted Space Cube (RSC 7m) & 10m Rail Combination

Restricted Space Cube Features

- Complies to AS/NZS1891.4 & AS/NZS5532

- Powder coated and galvanised steel fi nish complete with internal concrete and steel counterweights.

- Overhead anchorage point for personnel fall arrest.

- Ergonomically designed brake hand winch for raising and lowering vertical mast.

- Compact and counterweighted base that can be moved by forklift or hand pallet jack.

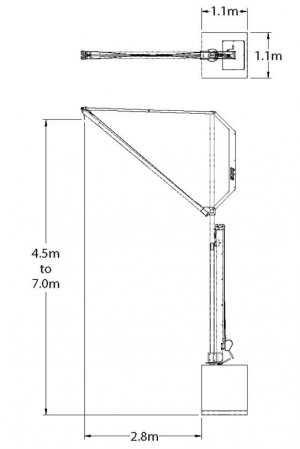

- Counter-weighted base has a footprint of 1.1m.

- Height adjustment of mast from 4.5m to 7.2m.

- Off set mast of 3m from central vertical mast.

- Product weight of (Restricted Space Cube assembly Only) 3.6T.

- Mast rotates 360° and can be locked every 22°.

- In-built visual overload and fall arrest indicators that identify if the RSC has been exposed to fall arrest forces or accidental misuse.

- Rated for (2) workers when two cubes are used in tandem and with an optional BTECH Rail & Trolleys.

- Optional accessories: Inertia Reels, Inertia Reel with Self Rescue Capability.

Horizontal Rail Features

- Provides 2 persons working at heights an overhead anchor point

- Modular design

- All trolleys feature back-up safety anti-drop brackets

- Minimum 5 wheel stability with 8 sealed bearings for trouble free movement.

- Large opening for ease of connection of Scaffold hooks and Karabiners.

- Meets the applicable requirements of the following standards: EN 795, OSHA 1926.502, ANSI/ASSE Z359 & AS/NZS 1891.2

Specifications Restricted Space Cube

| Ultimate Strength Rating: | 12 kN (18 kN with Rail) |

|---|---|

| Capacity Cube Only (Fall Arrest): 2 x Cubes With Rail: | Max. 1 worker weighing not more than 136kg. Max. 2 workers weighing not more than 136kg |

| Allowable MAF Rating for SRL’s: | 4 kN |

| Height: | 4.5 m Min. 7.2 m Max. |

| Reach: | 3.0 m |

| Foot Print: | 1.1 x 1.1 m |

| Weight: | 3.6 T |

| Anchorage type: | Limited Free Fall |

Specifications Horizontal Rail System

| System Capacity: | Two workers weighing a maximum 272kg including all clothing, tools, and equipment. |

|---|---|

| Arrest Force Rating for SRL: | 4kN Max |

| Weight (10m assembled rail only): | 95.5kg |

| Weight (trolley): | 1.48 kg each |

| Rail Construction: | Extruded 6061-T6 Aluminium |

| Uprights/Connectors: | Galvanized / Zinc-Plated Steel |

| Trolley Wheels: | Acetal with Sealed Ball Bearings |

| Hardware (minimum): | Grade 5 Zinc-Plated |

| Finish (aluminium): | Gold Anodized & Natural Finish |

| Plating Specification: | CS-500 Zinc Plated (Type II Zinc, SC-2, ASTM B633-85) |

| Standard Length:: | 9.756 metres Code: BTS0019B |

TRAINING:

Any worker using this equipment must receive appropriate training from their employer on all equipment involved prior to operating. All users must read and fully understand the product manual and any other instruction manual(s) relating to the system being used, or have the instructions fully explained to them before using this equipment.

In addition to training specific to this equipment, all users must be properly trained in the use of any accessories used with the system, as well as fall protection, confined space safety and any other applicable training related to the work being performed, in compliance with local regulations.

Document training records should be kept for all users of this equipment.

+61 2 8811 3500